Plated Bond

Three available wheel widths 30 mm (1.2 Inch), 50 mm (2 Inch) 61 mm (2.4 Inch)

NEW – RESIN BOND WHEELS FOR TRADESMAN EDGE BELT OVER WHEEL (REMOVING THE EXPENSIVE CONSUMABLES FROM THE SHARPENING GAME)

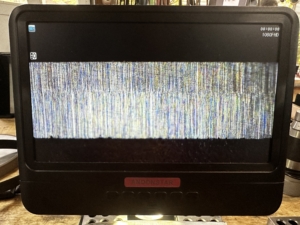

This picture is 400 grit resin bond on the top and a very smooth (old) 1000 Grit Plated bond on the bottom

As you can see the 400 Grit Resin bond Scratch pattern is smoother than the worn 100 grit plated bond.

In our main line of work (Tool and Cutter Grinding) Resin bond wheels are the weapon of choice.

Resin bond is ideal for a final pass near deburring,

Resin Bond wheels Cut.

Therefore are much better at creating a manageable burr across a spectrum of steels good and bad Making Honing a manageable process

Belt over the wheel on the right-hand side you have a wet inexpensive belt Quick Change

A wet resin Bond on the left (replaced the perishable 1000 grit CBN Plated bond)

The resin bond is a sharp deburring, finishing grit wheel that will never wear out

Honing, Leather, Composite, Felt With most any spray (Closed cell Neoprene works amazing)

Three Types of Belts for 2023

These are long life Belts

Resin Bond Aluminum Oxide 120 320 Grit

picture coming

Amecci Pyramid 800 1200 2000 Grit (Trizact Style)

picture coming

CBN 1 x 42 for Tradesman Blade 1200 grit

Diamond Resin Bond 1200 grit 2×42 for EDGE APEX (wet)

All of our Belts have a resin surface 120, 320 Are a compound Belt Meaning there is depth to the grit (bound in Resin)

Then in Trizact Style we have D35 (800) D 20 (1000) and D16 (2000) Grit