EDGE APEX 2024

Edge Apex Production Release May 2024

Accurate Easy fast and reliable (wont get damaged in shipping)

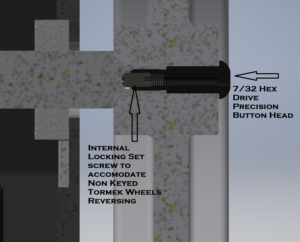

The 250 mm wheels that drive high speed belts and reverse are now keyed to our axles.

There is a new internal locking screw feature for people that want to use 3rd party wheels

This is a simple reliable assembly easy to produce and works well for all metal core wheel types

Being a heavier high speed reversing machine, accuracy and safety taken care of with the new shaft design.

The 2024 Edge Apex Unboxing

Jeffs’ Recent add ons for Tradesman 8, Scissors and Knife Sharpening

All Tradesman Grinders have these mounting locations

T8 Woodturner Knife Sharpening Kit $299.00

Edge Leading or Edge Trailing Uses the Apex Knife Jig and grip length Angle calculator

Fits all T8 Grinders 30 inch 12mm rail and a Knife Jig.

T8 Wood Turner , Tradesman Machinist, and Edge Apex, will all Mount this scissor attachment. (Just had to make Bracket)

Its Coming along Nicely 2024

Water mister systems and Ideas for belt grinders

We are going to use a similar system for the Edge Apex

Please have a look at the

Origin Blade Maker You Tube channel ) and subscribe Nice work !

Links for all the components:

Quick disconnects for airbrush: https://www.amazon.com/dp/B08Z43P1B7?…

Foot pedal: https://www.amazon.com/dp/B08MF2F8GF?…

Flexible nozzle: https://www.amazon.com/dp/B07X89Z1W9?…

8mm hose & fittings set: https://www.amazon.com/dp/B0BTJVBMQ8?…

Compressor with airbrush: https://www.amazon.com/dp/B07N64M2HM?…

Another place for information on setting up a mist system

Power Forge Workshop

Visit and Subscribe hes done some good research

Heres another

Friction Surfaces for Platens

Adhesive Back

Belts 1×42 and 2×42 Trizact Style Thick Resin Layer with embedded grit

These belts made by Amecci in Canada

Trizact Style (Thick Abrasive Resin on the belt face for long life)

We have D100 (220) D35 (800) D 20 (1000) and D16 (2000) Grit In Stock

JENDE Sprays and Other cool Kinfemaker goodies

Grip Length Calculator for Tradesman Blade E3 1 x 42 Blade Belt Grinder

Grip Length – Rail Setting Calculator for EDGE Apex 250 mm Wheel type Blade Grinder

How to make your own honing compound

Tradesman EDGE Apex Wheel Diameter Rail Zero Adjustment, good new stuff

When wheel diameters are different bring the rail to the wheel surfaces and Zero the rails

Then you are all set to use the angle calculator

Gary Creely, Creely Knives, has the new super steel alloys down to a science.

Apex Knife Jig for EDGE Apex and Bladesman 1×42 and 1X30 Belt Grinders

Each Knife Jig Comes with Driver for the Allen Screw , Clear Ruler for fast collar setting

Blade Centering, Quick set Collar, Thin Approach for real flat angles

Works with EDGE apex and Tradesman Blade Workstation and Tormek

Grip Length Calculator for Tradesman Blade E3 1 x 42 Blade Belt Grinder

Grip Length – Rail Setting Calculator for EDGE Apex 250 mm Wheel type Blade Grinder

Well-balanced and ergonomic quick-set collar, handle extensions available ,

Set the Grip length

EDGE Belt over Wheel for 2 x 42 250 mm Wheels Variable Speed Reversing Wet Belt

Edge 2 x 42 Belt over wheel Edge Accuracy Edge Composite Honing wheel

One set of 250 mm wheels can now last a for years!

One set of 250 mm wheels can now last a for years!

With the Belt over wheel, system you can use a belt grit of your choice for roughing in Apexes that

need a lot of material removed without wearing out your expensive wheels.

Keep in mind the Edge Apex is a wheeled machine the belt over wheel is a complimentary feature

Pop off the belt and finish with the wheel grit of your choice

Hone with the new EDGE Composite wheel and super-abrasive spray